+86 15633683072

Aluminum alloy container side box robot automated welding manufacturing line automation

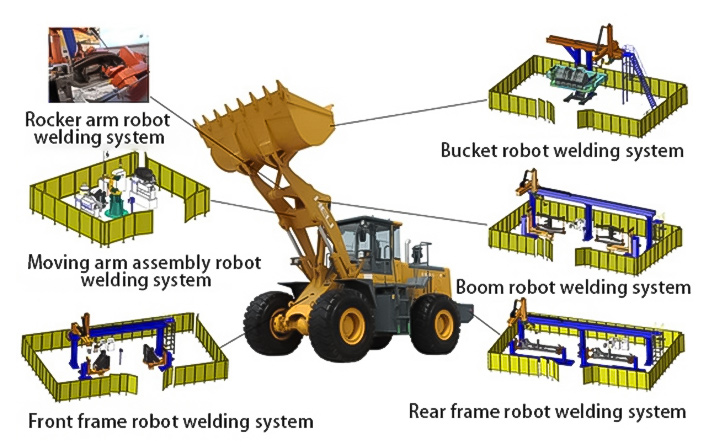

Aluminum alloy container side box robot automated welding manufacturing line automation  Loader Welding Production Line Automation Solutions

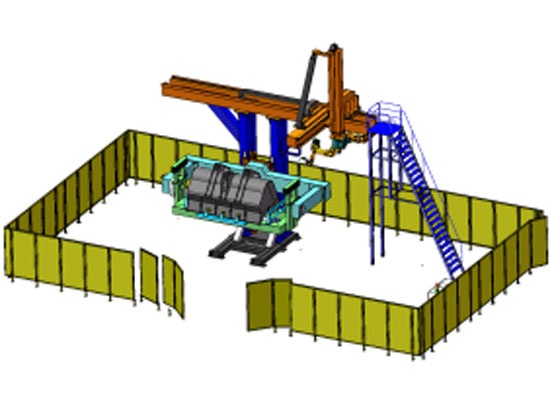

Loader Welding Production Line Automation Solutions  Bulldozer beam and bucket automated collaborative robot welding

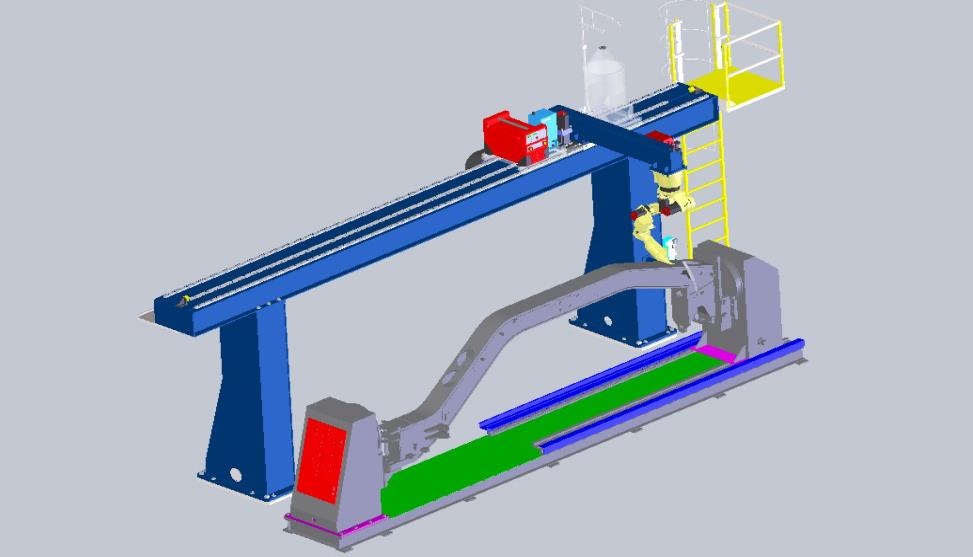

Bulldozer beam and bucket automated collaborative robot welding  Grader frame structure robotic arm for welding

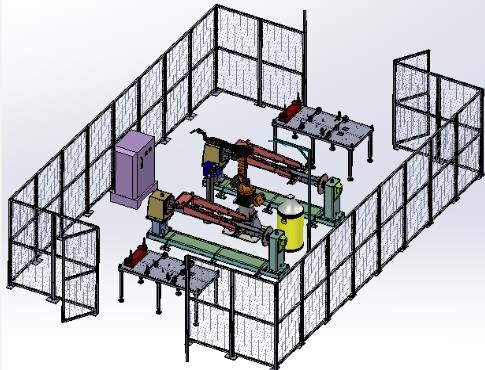

Grader frame structure robotic arm for welding  Corn harvesting machinery automation robot mig welding

Corn harvesting machinery automation robot mig welding Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com